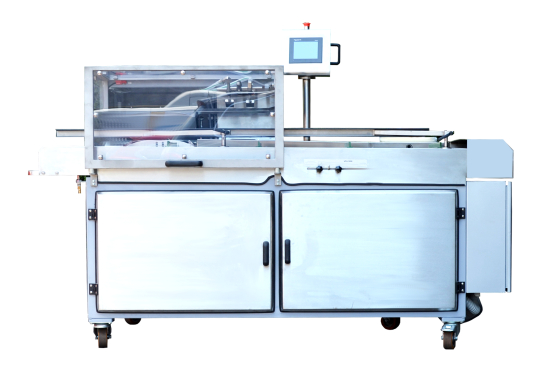

SLICER REX AND PACKING STATION

Characteristic

Capacity of up to 2,500 loaves of 1lb bread per hour, depending on the type of bread, browning, and cooling. It is normally performed on 11 mm thick slices, but it is possible to provide a machine with a thickness of 13 mm and 15 mm on request. The machine is equipped with a long-life, easily removable belt knife and is ready to be connected to the packing and clipping devices. Feeding the products is possible through the top, bottom or side tape conveyors that are adjustable with hand knobs. Stepless speed control of the tape conveyor is standard with all machines. The standard slicer is equipped with a synchronized bread collection system “one after another”, to the packaging line, a blade lubrication system for hard and heavy breads, as well as a sharpening device.

The device comes with a manual, spare parts list, wiring diagram and the EU declaration of conformity.

Additional options to increase productivity and efficiency for cutting and packing in a double blow molding machines and rotary table.

Order traders visit| Model | REX KT 11.45 | REX KT 13.45 |

| Efficiency when feed with / 1/2 lb loaves | 2500/2000 pcs/h | 2500/2000 pcs/h |

| Slice thickness [mm] | 11 | 13 |

| Max length of the loaf [mm] | 380 | 380 |

| Number of knives [pcs] | 16 | 14 |

| Electric power [V] | 400 | 400 |

| Control panel voltage [V] | 24 V/12 V | 24 V/12 V |

| Power [kW] | 4,18 | 4,18 |

| Power sockets | 3x400 V; 50/60 Hz; 5 kW | 3x400 V; 50/60 Hz; 5 kW |

| Weight [kg] | 766 | 766 |

| Dimensions: [mm]

- length - width - height |

2340 876 2000 |

2340 876 2000 |

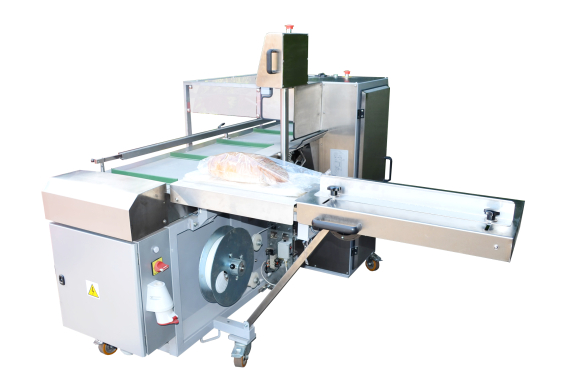

Packing station SAP

The automatic packing station SAP-3000 is used for sealing plastic and paper bags. The product is placed manually in the inflated bag, subsequently the bag is emptied of excess air and closed with a wire clip. Optionally, the clip can be dated. The device is equipped with wheels, controlled from a LCD panel to switch between automatic or impulsed operation mode, the clipping area is secured with a transparent cover.

Order traders visit| Model | SAP-3000 |

| Packing capabilities (size of a loaf) [mm]:

- length - width - height - distance from the clipper |

140-150 100-300 50-140 550 |

| Efficiency [pcs/min] | do 50 |

| Dimensions [mm]:

- length - width - height |

2150 1435 1210 |

| Weight [kg] | 275 |

| Power [V / Hz] | 400; 50 |

| Power consumption[kW] | 1 |

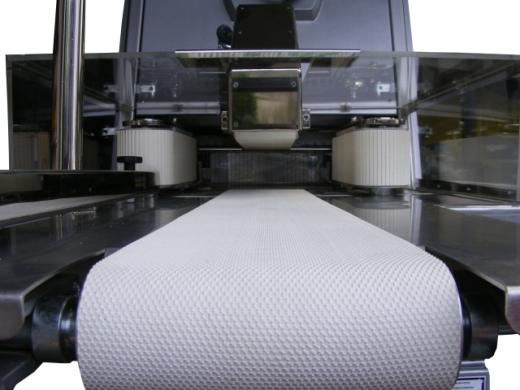

REX slicers touch panel

- lubrication of cutting knives in three ranges: low, medium and high

- low oil level in the tank

- receive bread

- opened doors left, right

- broken knife

- stop emergency button is pressed

- lack of phase sequence and low voltage indication phase

- operating hours counter

- the 5-speed feed belt speed and receiving control

The control panel touch screen produces the following messages:

Packing station advantages

- sucking air from the bags using suction devices to ensure adhesion of the bags

- additional air nozzle

- table height adjustment to the positioning clip as necessary

- air filter

- control by the LCD panel, two modes: manual and automatic

- body made of stainless steel AISI 304

- the machine body on casters with brakes

- all guards secured electrically

- the machine has a counter of wrapped loaves

- the installation of pneumatic connections suitable for continuous pressure of 6 bar, all parts made by FESTO, Germany.

Test our machines

Do you want to buy a new machine, but you are afraid that the purchased product will be a disappointment? How many times have you purchased a product that was insufficiently suited to your conditions and expectations? Make an appointment for a free test today and check how our machines will improve the work in your bakery. We will not convince you why you should trust us. You'll come to it alone. To arrange a free test and check how the spiral mixer works, just contact the sales department to arrange the appropriate date of our arrival. Video presentations

Concerns:

- Spiral mixers with fixed and removable bowl

- Slicers

- Mixers